Synthesis of porous nitrogen-doped carbon materials generated from fractal gels

Nowadays, porous solid adsorbents for gaseous or liquid separation are becoming very attractive for industrial applications. This project addresses this challenge by using the background of the group in colloidal science and polymer chemistry. Producing polymeric nanoparticles followed by the formation of a fractal gel permits the introduction of macropores in the order of 1- 2 μm diameter. Micropores inside the nanoparticles are then created by thermal treatment. This bimodal pore size distribution is necessary to achieve fast diffusion rate and good separation capabilities.

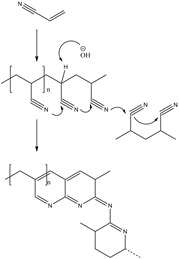

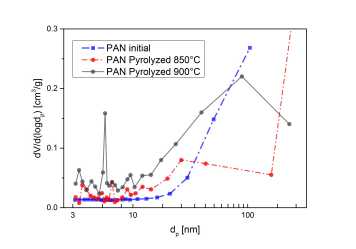

In the scope of this project, pure polyacrylonitrile (PAN) nanoparticles were synthetized by emulsion polymerization. The destabilization of the dispersion (e.g. gelation) is forming very open structures and is performed taking advantage of the kinetically favored aggregation behavior when the charges preventing this effect are screened. After drying, the material is thermally treated to form micropores. The thermal treatment consists of 3 parts: oxidation, stabilization and pyrolysis. The first part permits the cyclization of the neighboring cyanide functional groups along the polymer backbone and its dehydrogenation as illustrated in Fig. 1. The second part aims at finishing the stabilization already started during the oxidation. Those steps are very sensitive since without complete cyclization, the pyrolysis step will destroy the material. It is only above 800°C that micropores are created which can be seen in the pore size distribution in Fig. 2.

A possible application is the capture of CO2, where the presence of nitrogen in the matrix could be a great help towards selectivity. However, in gaseous applications, the pressure drop could cause difficulties due to the usual high velocities. These effects are carefully assessed in the modeling aspect of this project in order to find an optimal design of the pores. This material could also be a good candidate for other applications like separation in liquid chromatography or as catalyst support.

In conclusion, the project consists of 4 main steps: synthesis, gelation while controlling the macropores, thermal treatment for the control of the micropores and the final application.

Contact Person: Anna Beltzung